Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:bosuanji.cn

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

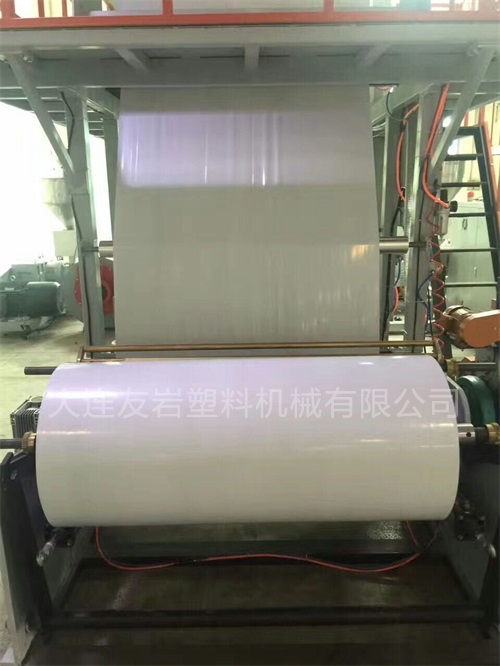

The market demand determines the future development of the three-layer co-extrusion film machine

The process of pushing is caused by the friction between the plastic and the screw and the plastic and the cylinder, and the collision between the particles, while the plastic melts because of the external heating of the cylinder. Three-tier co-extrusion blown film machine production line adopts the new type of high efficiency low energy consumption extrusion unit, the IBC film cooling system inside the bubble, + 360 ° for traction on the horizontal rotating system, photoelectric automatic correction device, automatic winding and film tension control, advanced technology such as computer screen automatic control system.

The three - layer coextruder film machine plays an important role in the plastics industry. Now most of the domestic existing film blowing machine factory, electric controlling part, general units are fitted with units operation counters, by the button according to the total power supply, open the main switch, motor, respectively through the toggle switch and control the fuselage and tee, market demand and need to improve the technology to produce market film blowing machine.

Three-tier co-extrusion blow thin line adopts the new type of high efficiency low energy consumption extrusion unit, the IBC film cooling system inside the bubble, + 360 ° for traction on the horizontal rotating system, photoelectric automatic correction device, automatic winding and film tension control, advanced technology such as computer screen automatic control system. Compared with the similar equipment, has a higher yield, good product plasticizing and the advantages of low energy consumption, easy operation, completely solve the film falbala and winding size top problem, make the product quality on a new step.

Based on the international market demand, such a huge self-supporting bag through long-term research and development and experiment, this equipment is mainly used in producing sterile liquid self-supporting bag packaging film, and cooperate with exxon mobil, develop higher performance of self-supporting bag film formula, its advantage to improve the traditional self-supporting bag film seal, and stiffness of the sterile and better performance, more in line with the future in liquid self-supporting bag the demand of the market.

Packaging integrity depends on the adhesion and tightness of each layer in the initial stage, depending on the change of adhesion during the shelf life. It can help merchants to make packing and seals in hot fill and distillation applications and other packaging that require initial pasteurization.