Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:bosuanji.cn

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

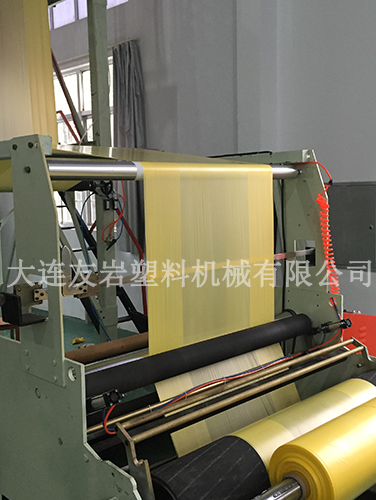

Most people don't know about plastic blowing machines

Blow Membrane is a kind of plastic processing method that refers to the process of heating and melting plastic particles into thin films. The quality of the film produced by this process is related to the machine and the plastic particles of the blowing film. If the film is blown out of the new material, the color will be clean and the finished product will be stretched. If plastic particles made from recycled waste plastics are often added to the film, the film may be inhomogenated, brittle and brittle, and low in price.

If the blown film produced by professional film blowing machine is suitable for all kinds of high-grade film packaging. This membrane is good for its obstructing, preservation, moisture-proof, anti-frost, oxygen and oil, and can be widely used in weight packing. If all kinds of fresh fruit, meat, pickles, fresh milk, liquid beverage, medical supplies, etc.

In the process of processing, the plastic film machine in dalian is not used in the correct way, so the film material can also be the second grade. Most PE is used for film processing film, general low density PE (LDPE) or linear low density PE (LLDPE) are available. HDPE film class is generally used for superior tensile and excellent impermeability. For example, the HDPE film is often used in merchandise bags, grocery bags and food packaging. PE film processing is generally used for ordinary blown film processing or flat extrusion process.

Inflating ratio is one of the key points in the production process of blown film. It is the ratio between the diameter of the bubble and the diameter of the tube. Blowing ratio of thin films of lateral expansion ratio, is actually to transverse tensile membrane, will have a certain degree of orientation effect of plastic molecules, blowing ratio increases, so that the film the transverse strength of progress. However, blow bilge ratio also cannot too big, cause film bubble to be unstable easily, and thin film is easy to appear fold. Therefore, the inflating ratio should be appropriate to the traction ratio. Generally speaking, the expansion ratio of low density polyethylene (LDPE) films should be controlled at 2.5 ~ 3.0.

The traction ratio refers to the ratio of the traction velocity of the film to the extrusion speed of the pipe ring. The traction ratio is a longitudinal stretching multiple, so that the film has a directional effect on the direction of the drawing. Traction ratio increases, the longitudinal strength and progress, and the thickness of the thin film thinning, but if excessive traction than, the thickness of the thin film is hard to control, and may even film break, broken film phenomenon. The traction ratio of low density polyethylene (LDPE) films is controlled between 4 and 6.