Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:bosuanji.cn

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

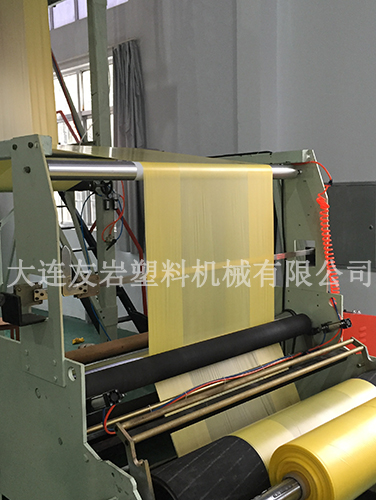

I'll tell you about the working principle of plastic blowing machines

The plastic blowing machine in dalian is a plastic particle heated to melt and then blown into a film. There are many kinds of plastic blowing machines, PE, POF, etc. The new material is blown out with new material, the colour and lustre are said, clean, the bag is stretched. Also somebody made from recycled plastic bags to the particle, the particle generally called the old material, made of particles is usually gray, usually to add pigment, when it made the bag made from bags to uneven color, brittle and break easily, the price is low. Although it is recycled plastic bags, it is generally a difference between the bag and the usual waste plastic.

Plastic blowing machine produces plastic membrane for all kinds of high-grade film packaging. The membrane is widely used for weight packaging because of its barrier properties, freshness, moisture, frost, oxygen and oil. Such as fresh fruits, meat, pickled vegetables, fresh milk, liquid beverage, medical supplies, etc.

Blow molding low-density polyethylene (LDPE) film, control extrusion temperature for half a year between 160 ℃ to 170 ℃, and must ensure the temperature uniformity in the nose, extrusion temperature, resin is easy to decompose, and film brittle, especially make the longitudinal tensile strength decreased significantly; Plasticizing temperature is too low, resin, not smooth to stretch, the tensile strength of the film is reduced, and the surface gloss of the very poor transparency, appear even like wood ring pattern and fisheye did not melt.

Bloating ratio is one of the main points of control for the production of blown thin film, which is the ratio between the diameter of the bubble and the diameter of the pipe that is not inflated. Blowing ratio of thin films of lateral expansion ratio, is actually to transverse tensile membrane, will have a certain degree of orientation effect of plastic molecules, blowing ratio increases, thus increase the lateral strength of thin film. However, the expansion ratio cannot be too big, otherwise it is easy to cause the membrane to be unstable, and the film is prone to wrinkling. Therefore, inflating ratio should be appropriate to the traction ratio, generally speaking, the expansion ratio of low-density polyethylene (LDPE) films should be controlled at 2.5-3.0.

Because after the blow molding of polyethylene film for printing or composite processing technology, subject to the effect of mechanical force, therefore, requires physical and mechanical properties of polyethylene film should be fine, including tensile strength, elongation at break, tear strength several indexes such as standard.